Design Process

As a professional artist I enjoy making my client’s visions come to life. Often the patron has a definite subject or theme in mind. Others prefer to develop their ideas by perusing my portfolio of designs for inspiration. Some will bring in photos of windows or scenes that they find attractive or memorable, so that I am able to have a sense of direction for their desired piece.

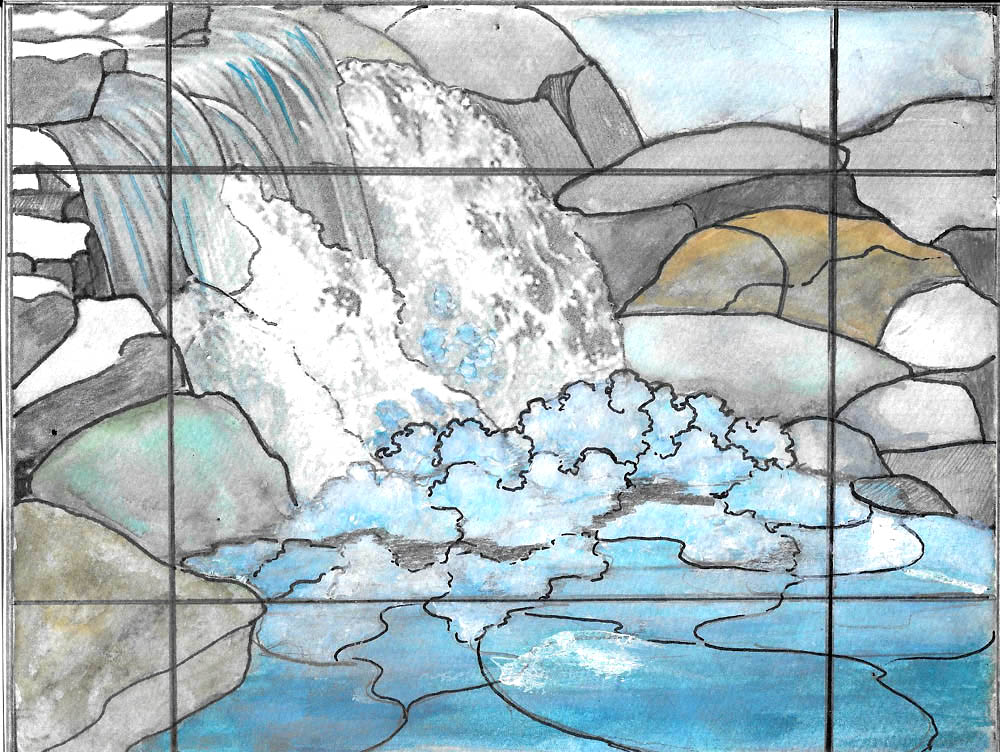

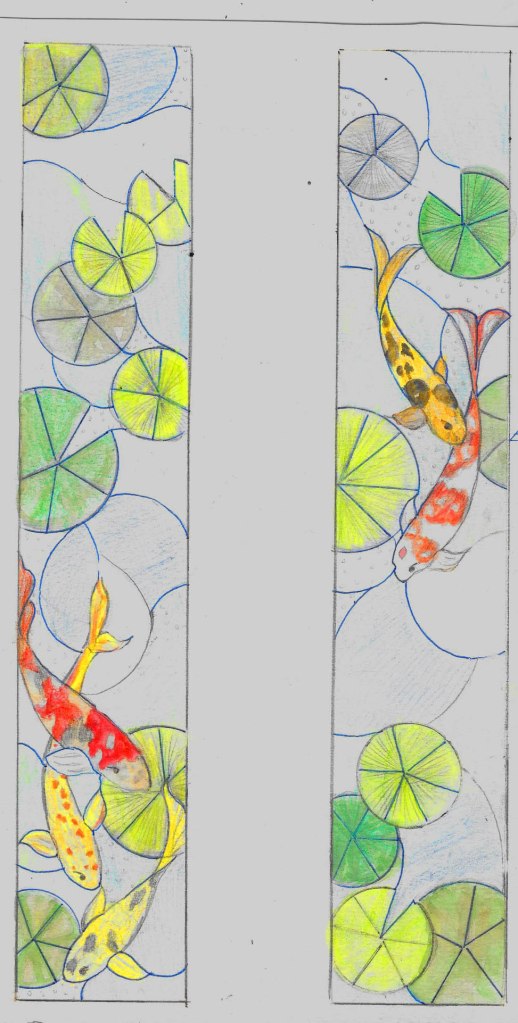

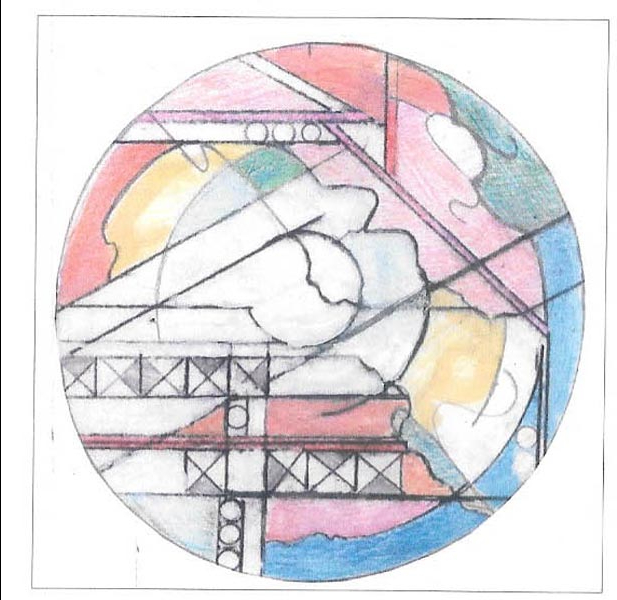

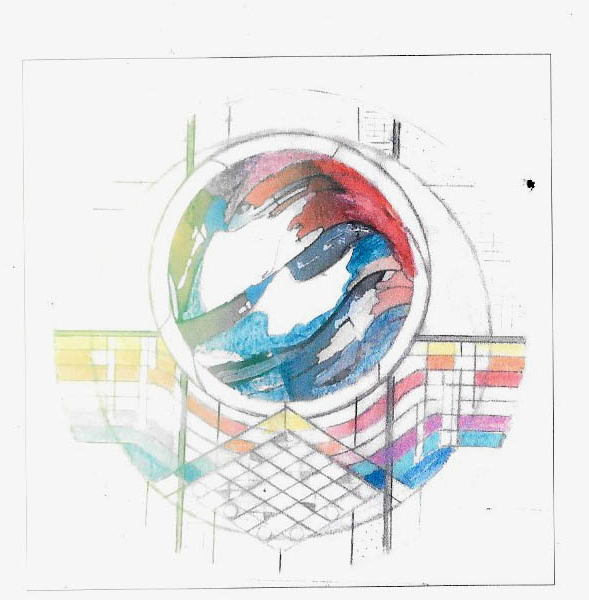

The next stage is the preparation of a small scale drawing. This drawing is done in watercolors and inks, which gives an accurate visualization of the finished window. Art glass samples, clear, textured, or colored, are presented for approval. Important aspects are considered and discussed, such as degree of privacy desired, color palette to complement the home decor, and ambient light available. The glass must take advantage of strong sunshine and cool shadows, twilights and high noon.

Upon approval of the design and proposed materials, production ensues. The building of the panel then follows the same basic steps as windows produced hundreds of years prior. A full scale cartoon is developed, then individual glass pieces are cut and joined together in a lead matrix which is soldered where joints meet. Next the window is cemented, cleaned and reinforced before installation in the home – providing years of enjoyment.

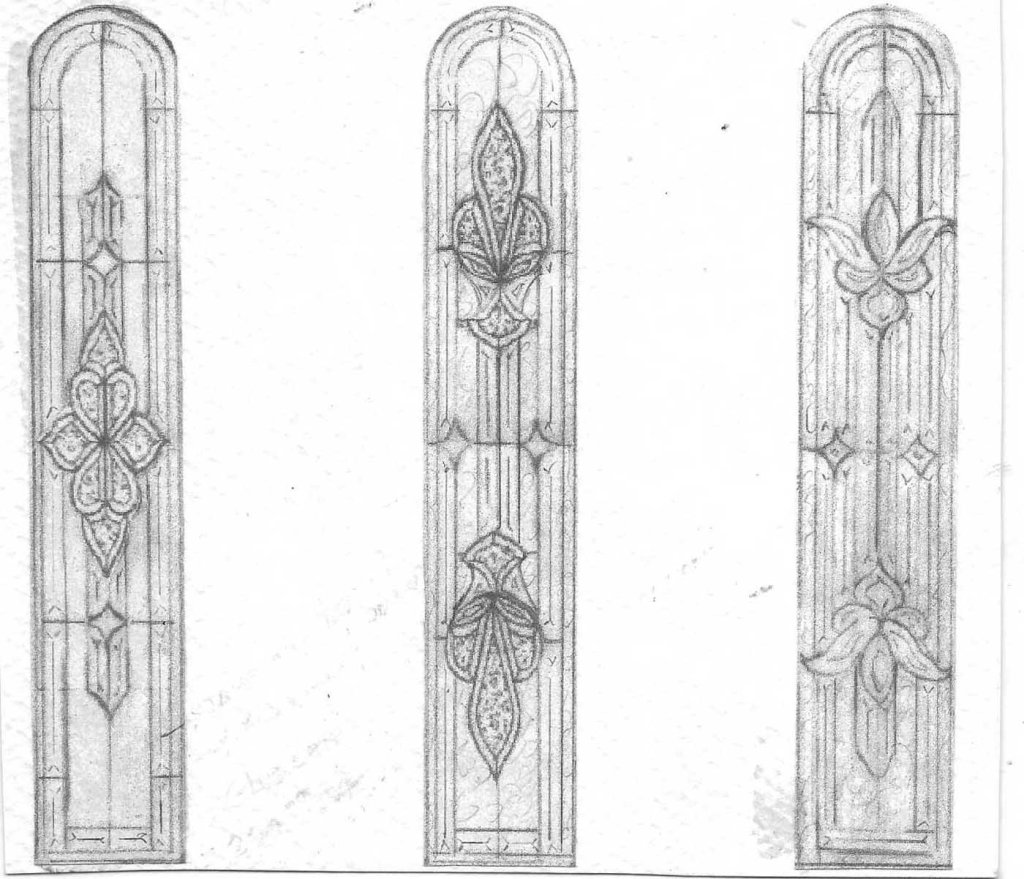

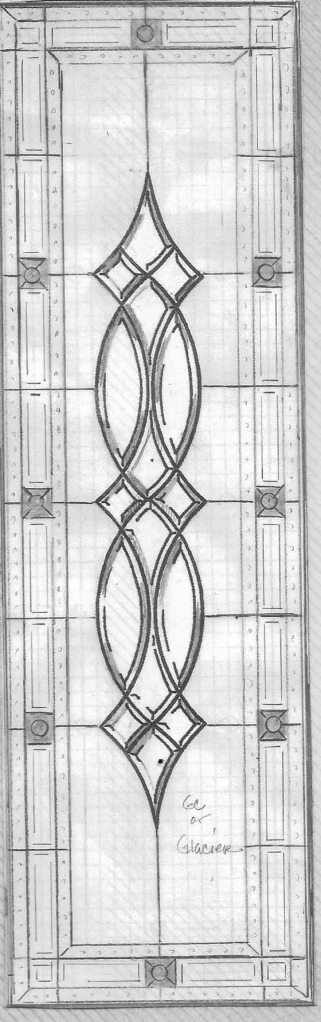

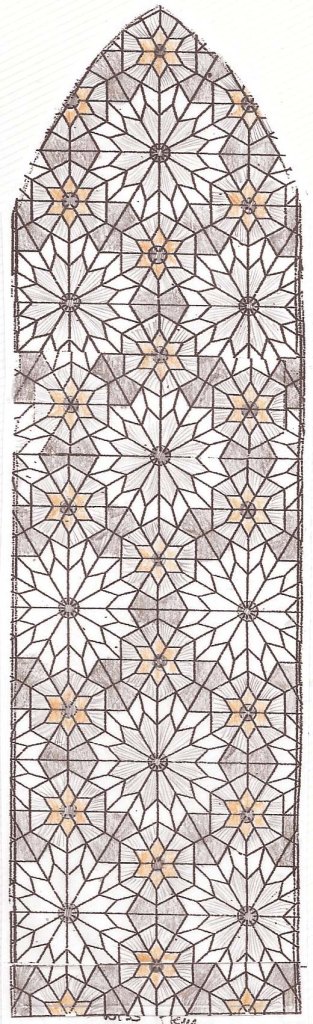

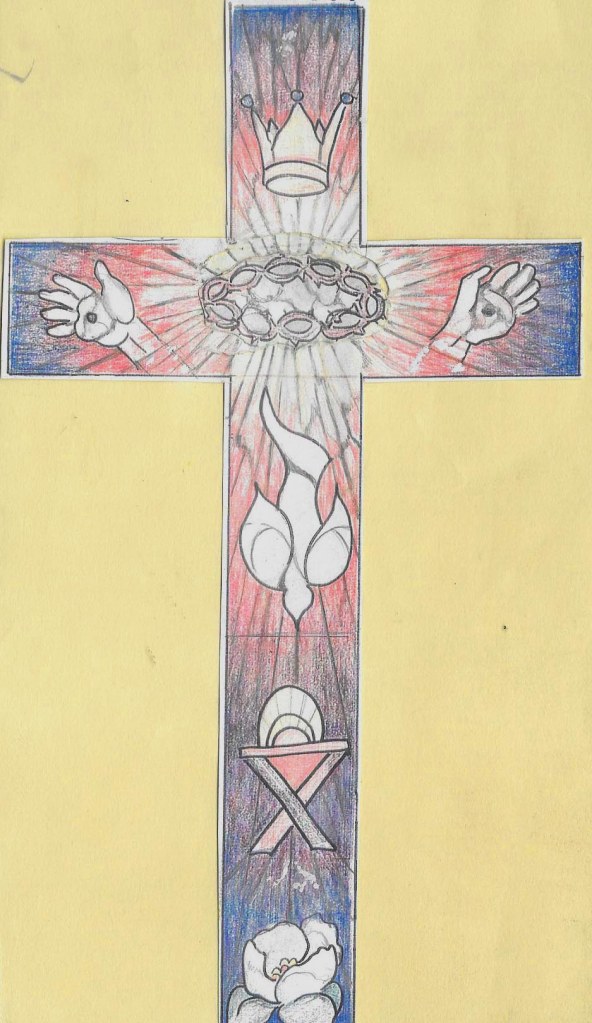

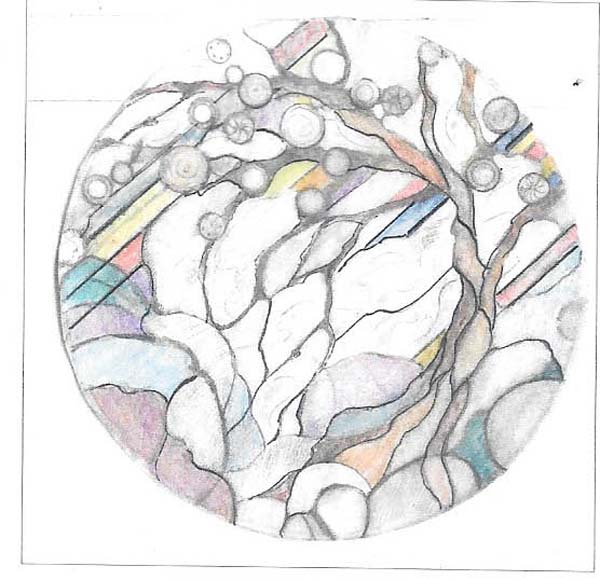

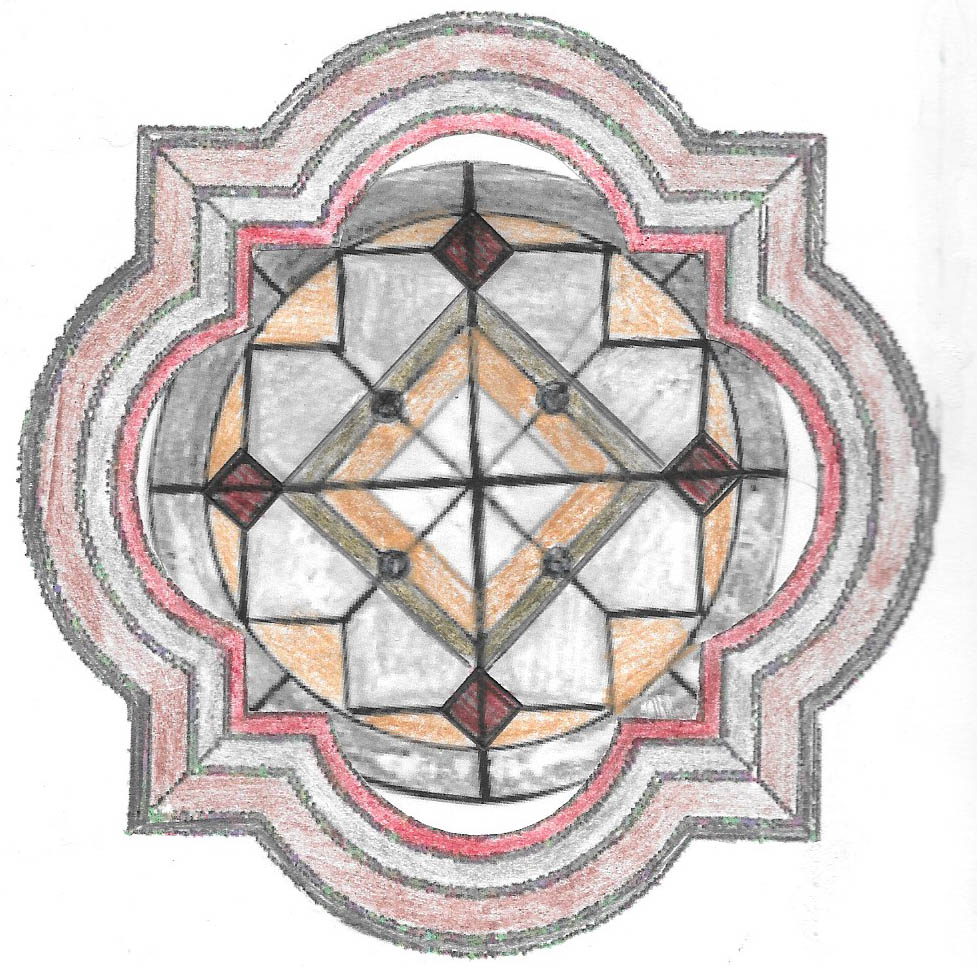

The preliminary drawing:

A deeper look at our portfolio of sketches

A professional glass artist needs to be skilled in visual communication, working with color to set mood, character and spirit. These preliminary sketches were the ground work for several stained glass projects. When they were translated into finished glass works, the special alliance with light and color created a beautiful environmental translation.

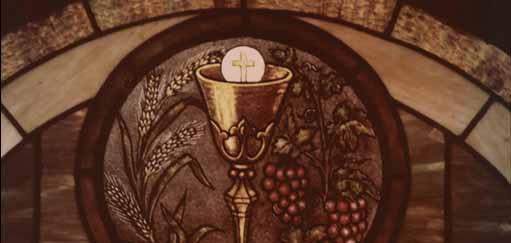

Kiln-fired glass

This specialized technique has been used for centuries to create minute and inspiring detail. Using vitrous metal oxides as a paint, the artist meticulously draws the design on glass which is then fired in a kiln to bond with the glass making the colors permanent. Often many layers and firings are needed to create the desired effect.

Scarab Glass Works | 559.486.5480 | scarabglass@hotmail.com